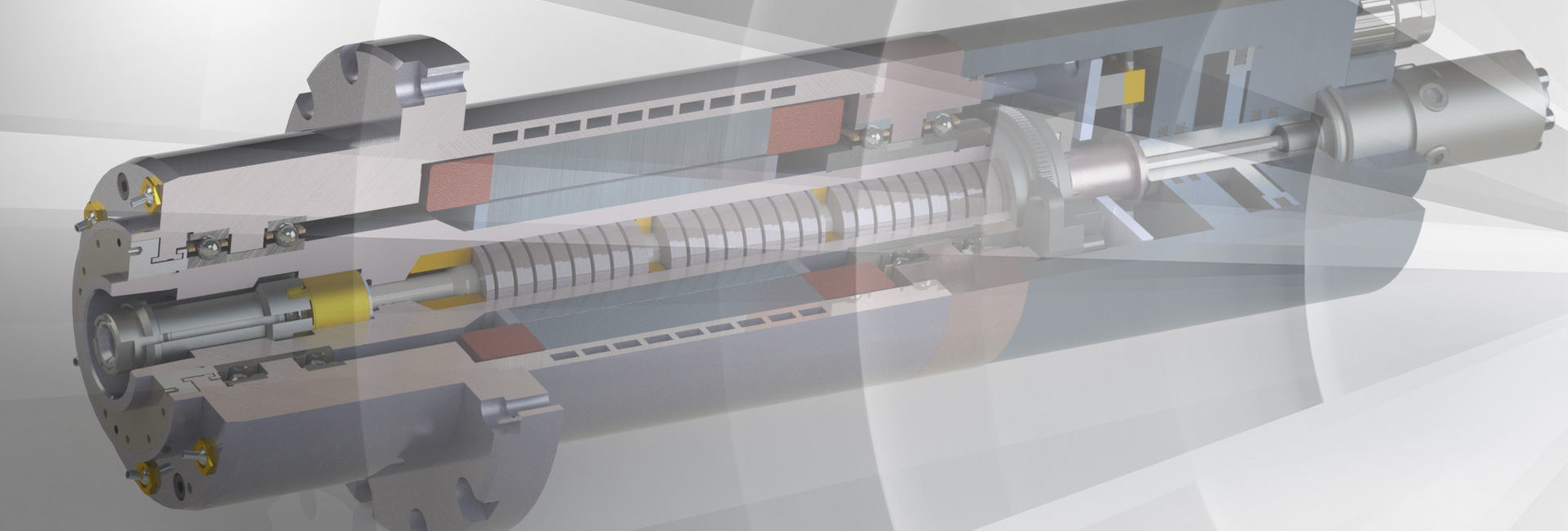

Technology

Renaud technology

Based on our standard range or in the case of developping a new project, our engineering and design department will integrate various technologies in our products, basic or advanced, in order to provide our customers a spindle which meets their needs and offers maximum efficiency.

The form

Robert Renaud SA produces spindles with specific dimensions, in cylindrical or parallelepipedic form, fixed by flange, feet or others. We also realise spindles in particular materials, able to resist highly aggressive environments.

The bearings

Our spindles can be equipped with high precision bearings with preload:

- fix

- by springs

- hydraulic

- by grease (lifelong)

- minimal air-oil

- minimal oil (injection through outer ring)

The interface of tooling systems, respectively of toolholder

We realize various interfaces:

- standard like : HSK according to DIN 69893, ISO tapper according to DIN 69871, MAS 403, ANSI B5.50, collets of SCHAUBLIN company or others

- special execution, according to the data provided by the customer

- manual

- automatic

- pneumatic

- hydraulic

- by external action

Drive

Our spindles can be driven by an external element, such as for example a belt

Or our electrospindles, offering power-torque characteristics corresponding to the speed required by our customers and driven by:

- normalized motor which can be equipped with

- simple ventilation

- forced ventilation

- brake

- HF motor integrating technology

- asynchronous

- synchronous

- with cooling of the type

- liquid

- by air

- natural convection

Protection in dirty environment

Our spindles can be equipped with:

- cleaning of the tapper and/or the face by compressed air

- simple effect air seal at the spindle nose

- effective air seal at the spindle nose (immersed environment)

Data acquisition

Our spindles can be equipped with:

- sensor « spindle stop »

- angular encoder for shaft positioning

- position sensor of tool clamping:

- clamped

- unclamped

- at rest

- measuring and compensation system of the dilation

- temperature measurement of front and/or rear bearings

- vibration sensor

- integrated system of self-balancing

- tool - part contact sensor

- power sensor

- static force sensor

- dynamic force sensor

Integrated mechanical technology

Our spindles can be equipped with:

Brake:

- pneumatic

- hydraulic

- electromagnetic

- manual

- pneumatic

- hydraulic

- electromagnetic

Cooling system

Our spindles can be equipped with:

- cooling through the shaft

- with high pressure by rotary union

- for high speed spindle by rotary union without contact

- auxiliary cooling nozzles

Inquiry for development

Filling and returning us the form inquiry for development will allow our engineering and design department to submit you a proposal.